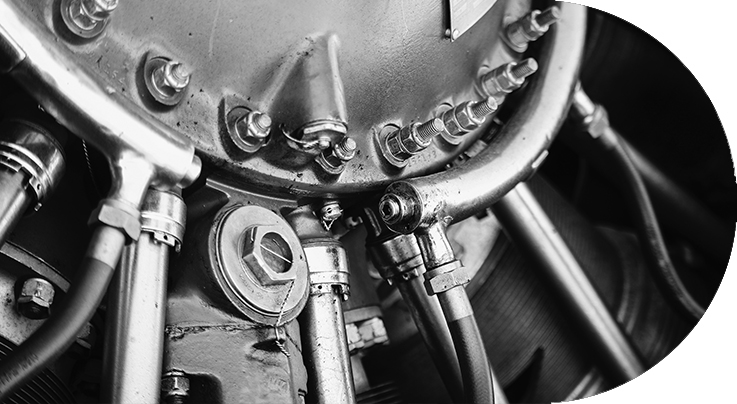

Al Hakim has a complete in-house machining shop and is able to meet the most stringent specifications, no matter what the type of product. A dedicated team of experts handle these value- added services, ensuring that customer needs are met on time and to specifications, consistently monitoring quality and performance to the highest international standards.

These value-added services include:

With 10 years of experience of handling customer requirements, Alhakim also demonstrates excellence in providing Innovative value-added services. Our Valve Automation Center has been providing automation solutions since 2011 and we are committed to continually enhance our services and products with cutting edge technology.

Our Machining Division and our Valve Division are ISO 9001:2008 certified for their Machining and Valve Assembly, Automation and Pressure Testing services.

With a complete Valve Automation & machining shop, Al Hakim is able to meet the most stringent specifications, no matter the type of product. A dedicated team of experts handle these value-added services, ensuring that customer needs are met on time and to specification, consistently monitoring quality and performance to the highest international standards. Contact us for more